One example of a curing process done in a curing oven is powder coating, which is a kind of curing, is the process of applying a powdered thermoplastic resin to a surface by means of static electricity. When exposed to heat in a curing oven, the powder gels and forms a protective layer on a product’s surface. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Curing Oven Manufacturers

What is a Curing Oven?

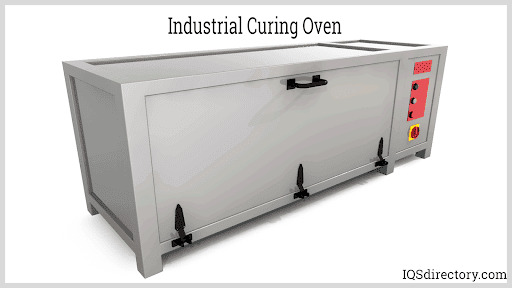

A curing oven refers to thermal processing equipment used by thermal specialists to improve or enhance materials' strength and durability.

Numerous factory processes, including drying, baking, cooking, heating, and curing, require industrial ovens to produce a specific outcome. In the oven, a material is heated to accelerate the required chemical reaction.

How Curing Ovens Function

A curing oven's operating principle is based on heat sources and air circulation patterns.

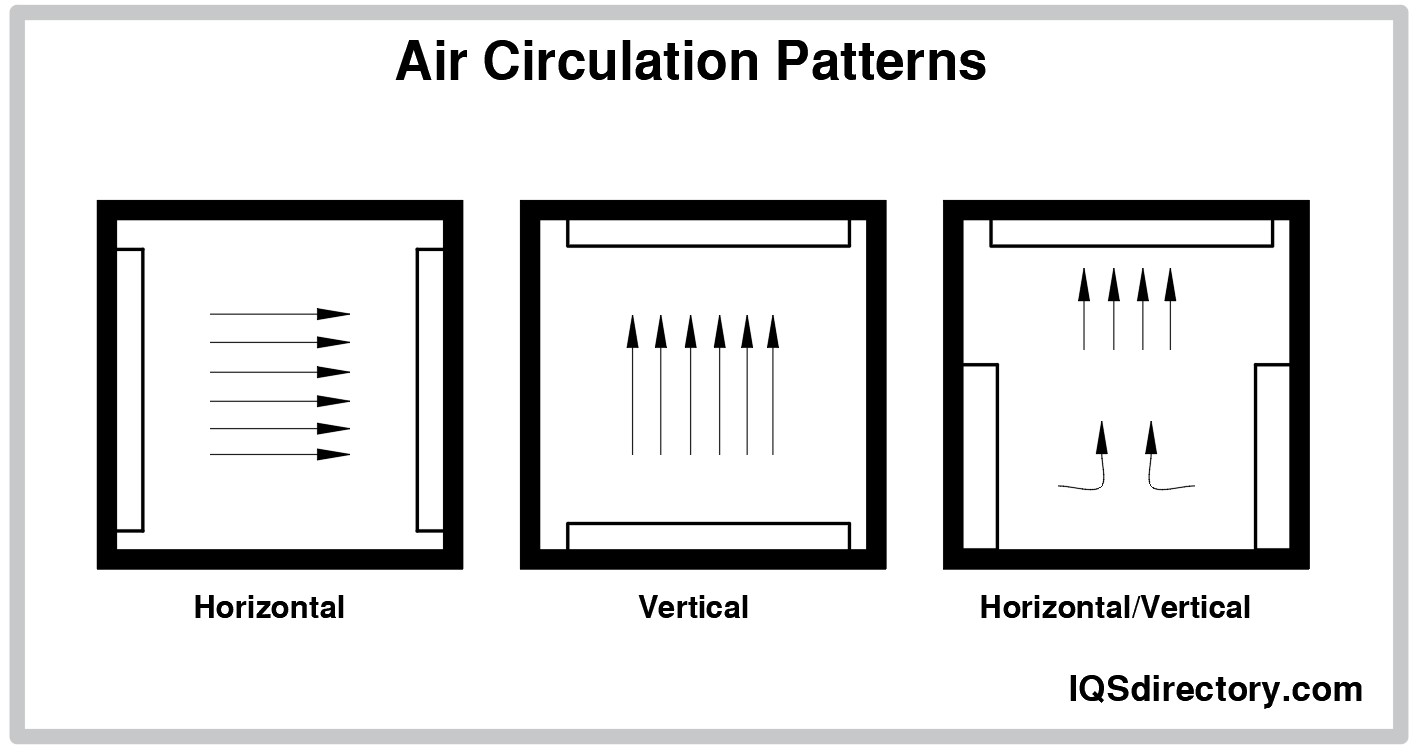

Air Circulation Patterns

Air circulation patterns refer to the air distribution in the oven. The oven's airflow plays an important job because the generated heat needs to be controlled to prevent distorted materials or even explosions.

The types of airflow are vertical/horizontal flow, fully horizontal flow, and vertical flow. Vertical/horizontal flow is a type of flow where the air enters the oven by the sidewall and is returned through the oven's ceiling. This type of flow is ideal with large parts.

Next, full horizontal flow is mainly used when the material to be processed is hung and when the contained parts are small and have to be placed on perforated shelves. In full horizontal flow, the air passes above and below the shelves from sidewall to sidewall.

Finally, in vertical flow, the processed material is put on shelves, but there must be room for the air to flow from the sidewall below to the sidewall above. The vertical flow pattern is also used for small hanging parts.

Heat Sources

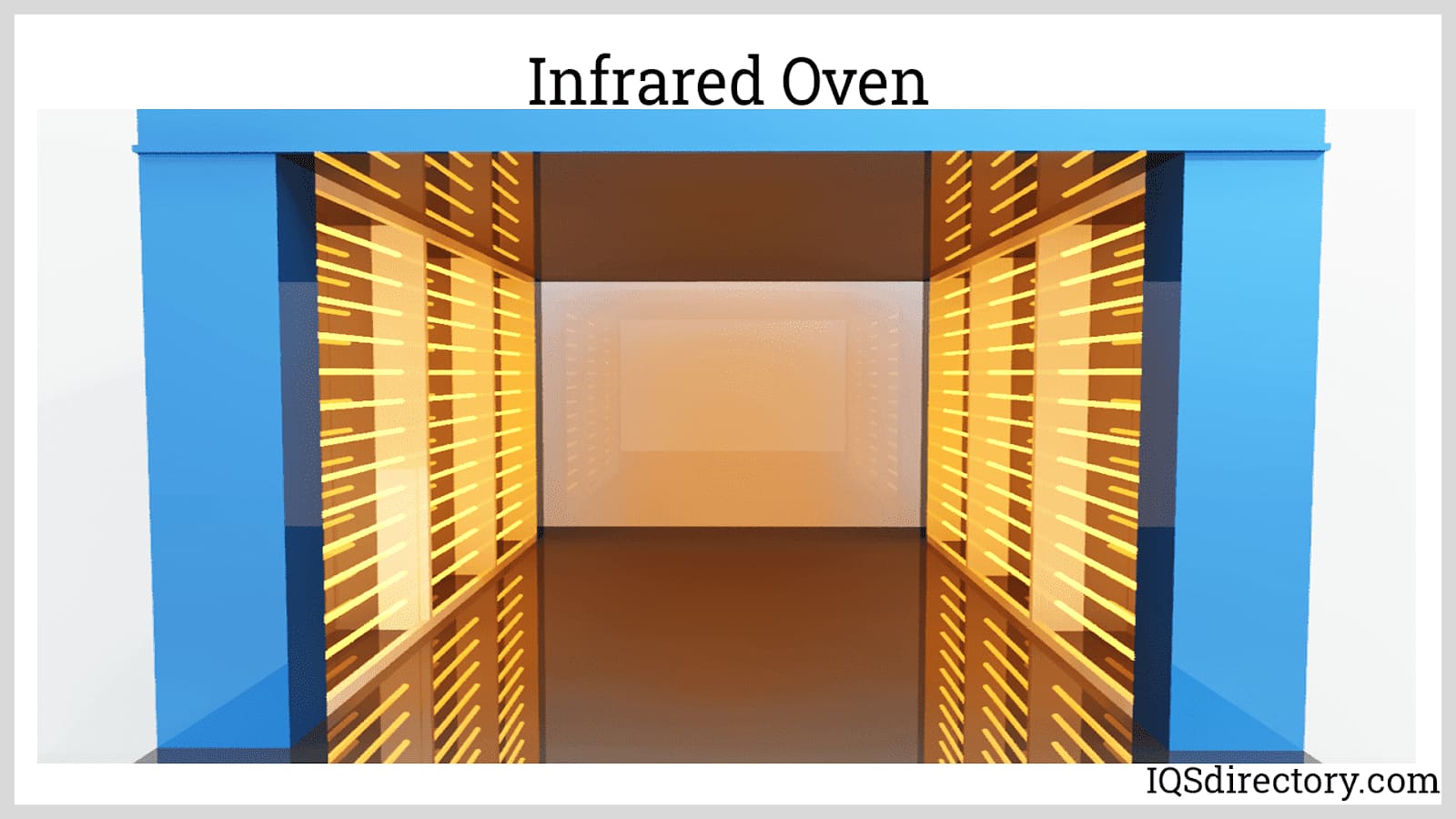

Some of the main sources of power for heat are steam, direct gas, electricity, oil, indirect gas, hot water, and ultraviolet light. These heat sources can also be used to classify the ovens.

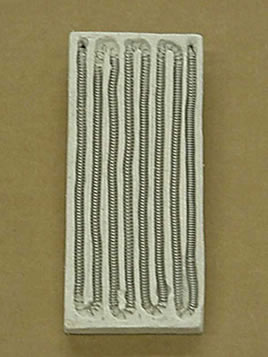

Electric heat ovens use electricity to heat the elements, producing a result of the temperatures required for the chemical reactions to begin.

In direct gas ovens, the gas flames are directly on the material to be processed. Indirect gas ovens use the gas flames indirectly over the processed material.

Types of Curing Ovens

There are two main types of industrial curing ovens: batch ovens and continuous processing ovens (also known as constant process ovens).

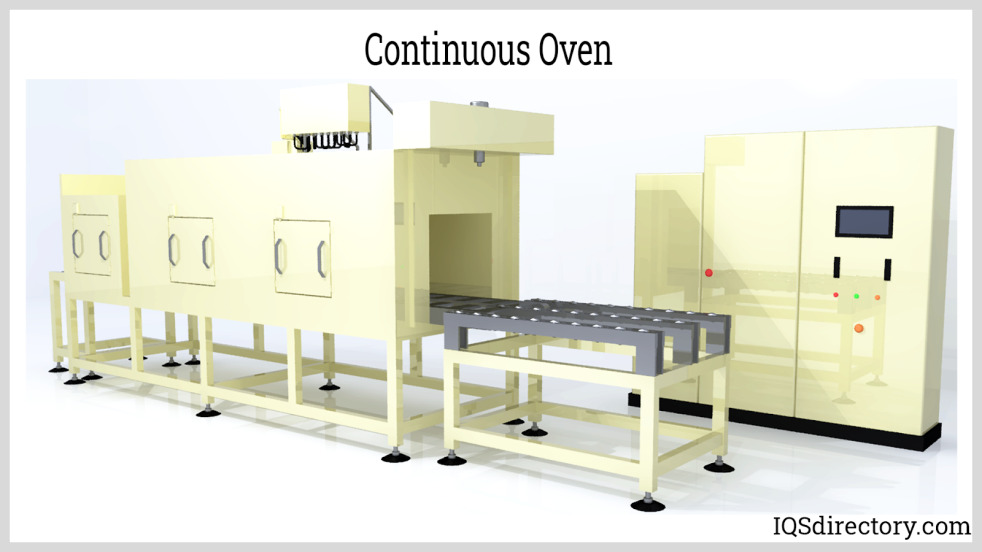

Continuous Process Ovens

This type of curing oven operates by using a powered transport method such as a conveyer to expose parts or materials to heat at a predetermined rate. This process usually requires one operator to monitor and carry out the process.

The calculations in this process are made according to how much the material will be exposed to the heat inside the oven.

A conveyor system moves the parts in and out of the oven. Continuous process ovens are made up of parts including pumps, nozzles, insulated panels, chains, pipe fittings, flame rods, blowers, pressure switches, burners, drives, air kits, transmissions, regulators, tooling, fixtures, controllers, fuses, and conveyors.

Batch Process Ovens

Batch ovens operate by placing parts in the oven over a period. These ovens have numerous designs, some of which allow the parts to rotate inside for an even heat distribution. However, some of the designs will have stagnated parts.

The parts are unloaded and loaded into the oven using transportation carts, after which the doors are closed. The batch process takes a lot of material handling and needs many workers to set up the process, making it a disadvantage over the continuous process.

Applications and Uses of Curing Ovens

One application of curing ovens is curing adhesives. Some adhesives are cured at room temperature depending on the strength of the bond, while some require heat.

Curing is also used to heat painted surfaces after painting, thus making the water in the paint mix evaporate effectively.

There is also the curing of polymers whereby liquid low-weight polymers are changed to solid, infusible 3-D polymers. This process is irreversible.

Choosing the Correct Curing Oven Manufacturer

To ensure you have the most beneficial outcome when purchasing a curing oven from a curing oven manufacturer, it is important to compare several companies using our directory of curing oven manufacturers. Each curing oven manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each curing oven business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple curing oven companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches