Brazing ovens are widely used in industrial brazing applications because they lend themselves to mass production and because they are easily operated by unskilled laborers. Furnace brazing is a better method for mass production than other brazing methods for a number of reasons. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

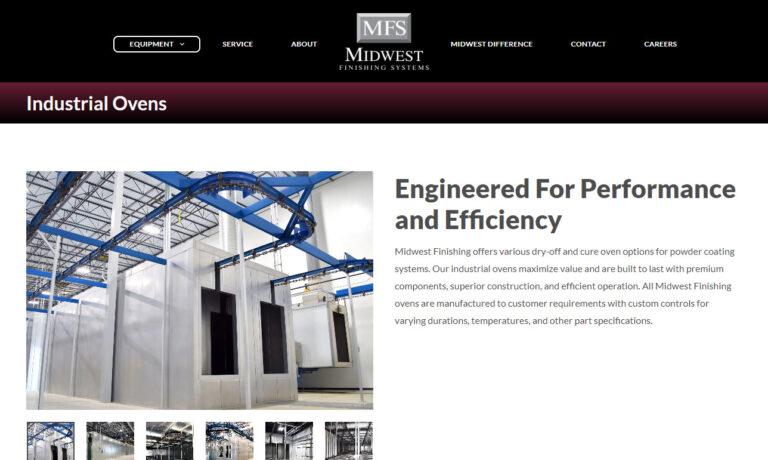

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Brazing Oven Manufacturers

First is the ease with which brazing ovens can produce large numbers of small parts that are self-locating or easily jigged. Additionally, because brazing ovens use controlled heat cycles, this process allows the use of parts that would likely distort under localized heating and eliminates the need for post-braze cleaning.

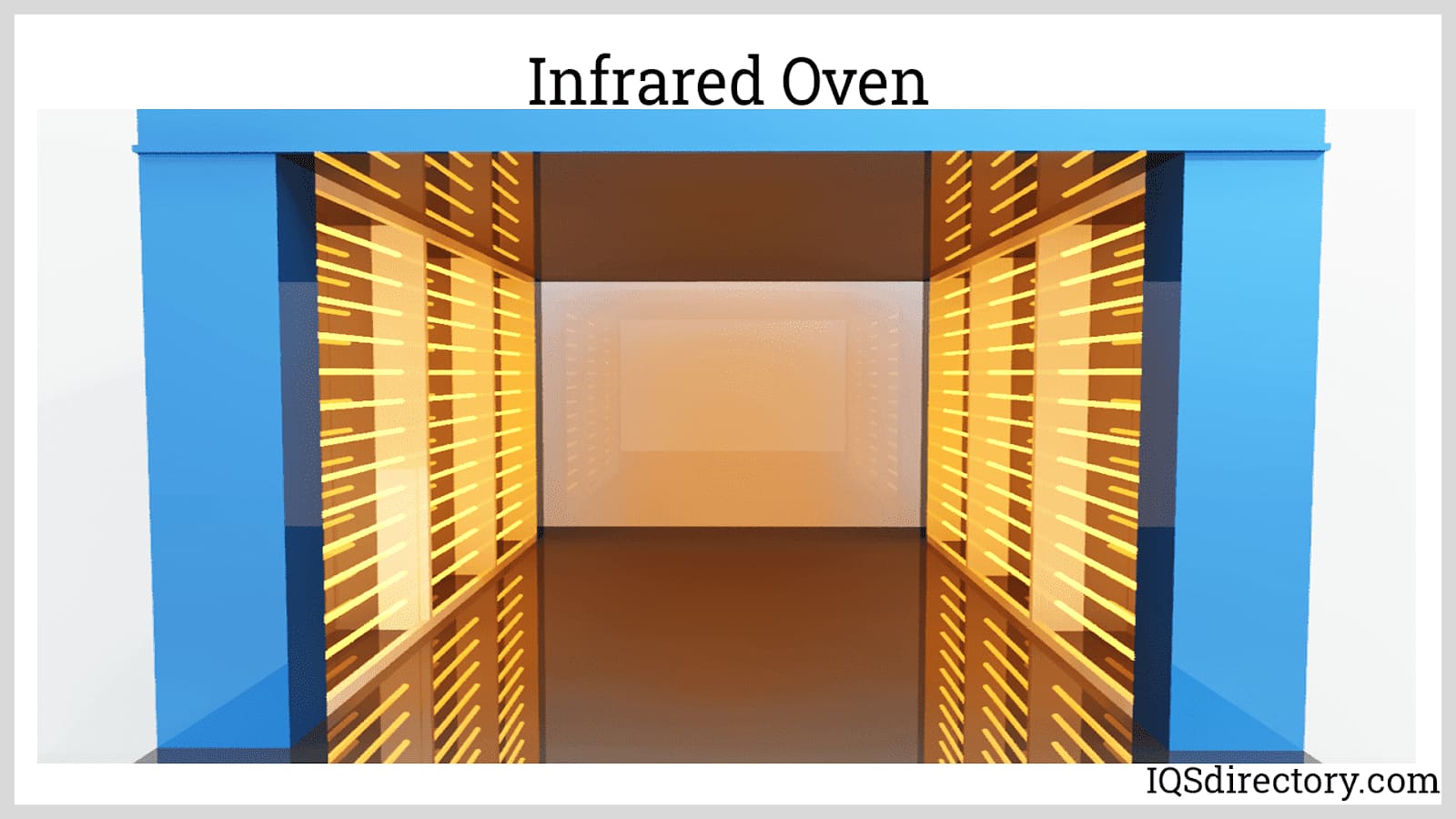

Brazing oven atmospheres offer another advantage by providing the metal part protection against oxidation. Common atmospheres include inert, reducing and vacuum atmospheres. Other advantages of using brazing ovens include: low unit cost when used in mass production, close temperature control and the ability to braze multiple joints at once. Ovens are typically heated using gas, electricity or oil, depending on their application and type.

There exist four main standard types of brazing ovens from which a potential customer may choose for his or her brazing operation: batch, continuous, retort with controlled atmosphere, and vacuum. Batch type brazing ovens offer the advantage of relatively low start-up costs, and they can heat each part load separately. Additionally, the ability to turn them on and off at will reduces overall operating costs.

Batch type brazing ovens are best for medium to large volume production, but they offer a large degree of flexibility when it comes to what types of parts they can braze. To control oxidation and cleanliness, batch ovens are compatible with both controlled atmospheres and flux. Continuous type brazing ovens best serve a steady flow of similarly sized parts, frequently fed through the oven's hot zone on a conveyor belt.

They most often use controlled atmosphere or pre-applied flux. Because they offer the benefit of very low manual labor requirements, continuous ovens are a great choice for large scale operations. Retort ovens stand apart because they have a sealed lining called a "retort." Said retort is generally either sealed with a gasket or welded shut, filled completely with the intended atmosphere and heated externally by conventional elements.

It is almost always made of heat and oxidation resistant alloys. Retort ovens may be built as batch or semi-continuous models. Finally, vacuum type brazing ovens are a relatively economical method of oxide prevention, most often used to braze materials with very stable oxides that cannot be brazed in atmosphere ovens, like aluminum.

Vacuum brazing ovens are also relied upon for the brazing of refractory materials and other unconventional alloy combinations unsuited to atmosphere ovens. Since these ovens do not have flux or a reducing atmosphere, part cleanliness is of the utmost importance. Vacuum ovens, which are most commonly batch type and suited to medium and high production volumes, come in three main types: single-wall hot retort, double-walled hot retort and cold-wall retort.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches