The finish is also long lasting and near pollution-free, as the waste dry spray that is applied at the beginning of the process can be recovered. Consumer grills and barbeques, stadium seating, outdoor railings, golf clubs, farm equipment, exercise equipment and many other varieties of consumer and industrial products undergo powder coating. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

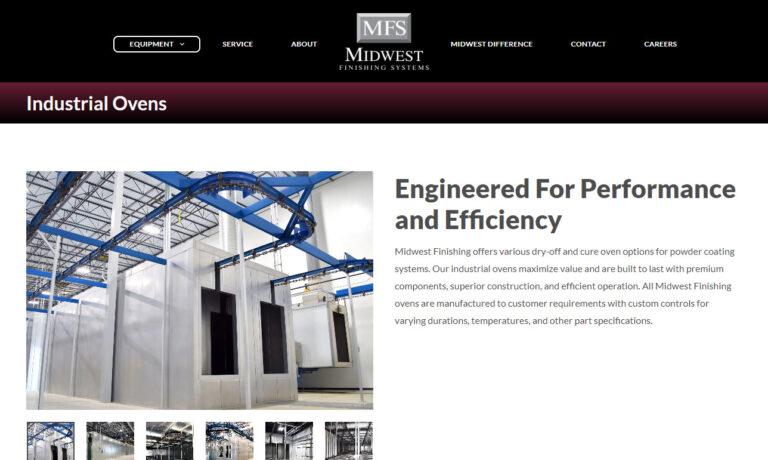

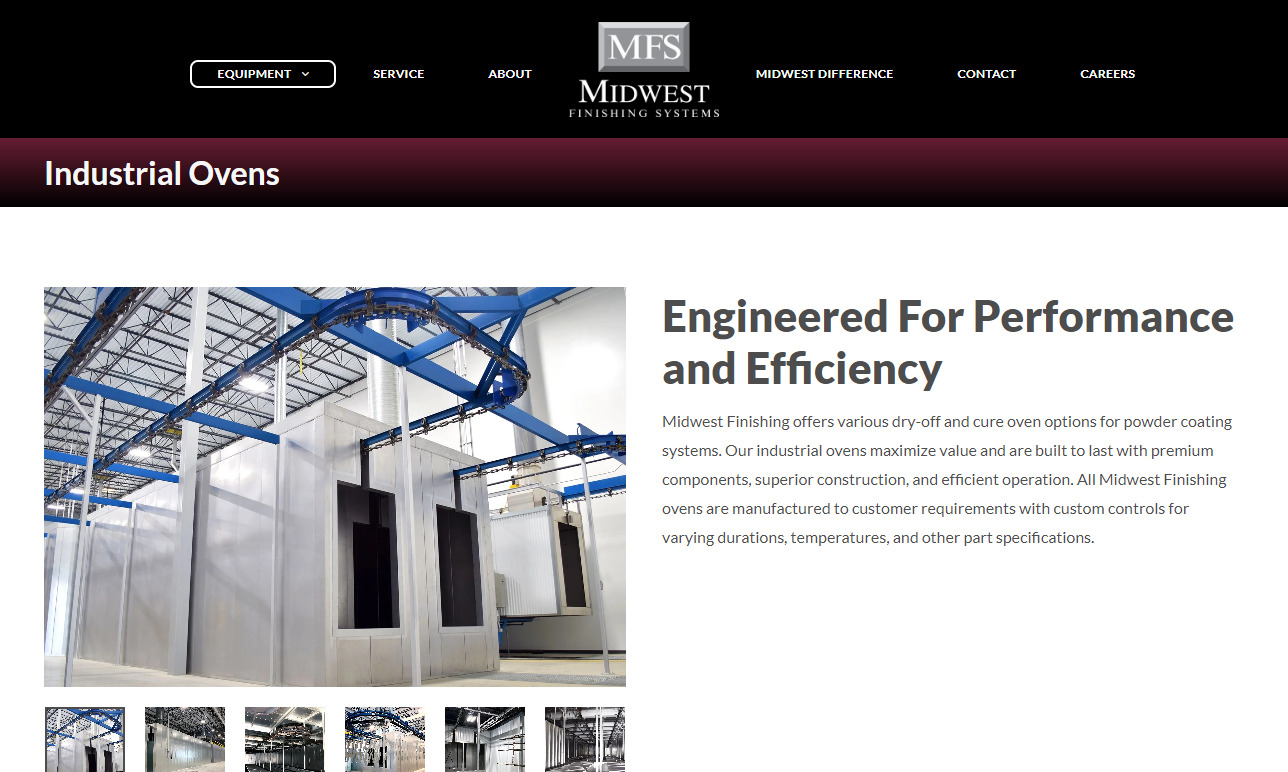

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Powder Coating Oven Manufacturers

The industrial oven manufacturing industry provides the powder coating services industry with tools for the thermal processing stage of treatment; many products are powder coated, so the industry requires many ovens that can treat products efficiently and in high volumes.

The process of powder coating is mostly standardized. A technician will begin with the product that needs to be treated. It must first be cleaned, sometimes sandblasted and free of oil and paint before any treatment can be applied. Once cleansed of unwanted elements, a special applicator gun is used to coat the product with pigmented thermoplastic particles. When the product is coated, it is sent to a powder coating oven where it is heated for two to ten minutes.

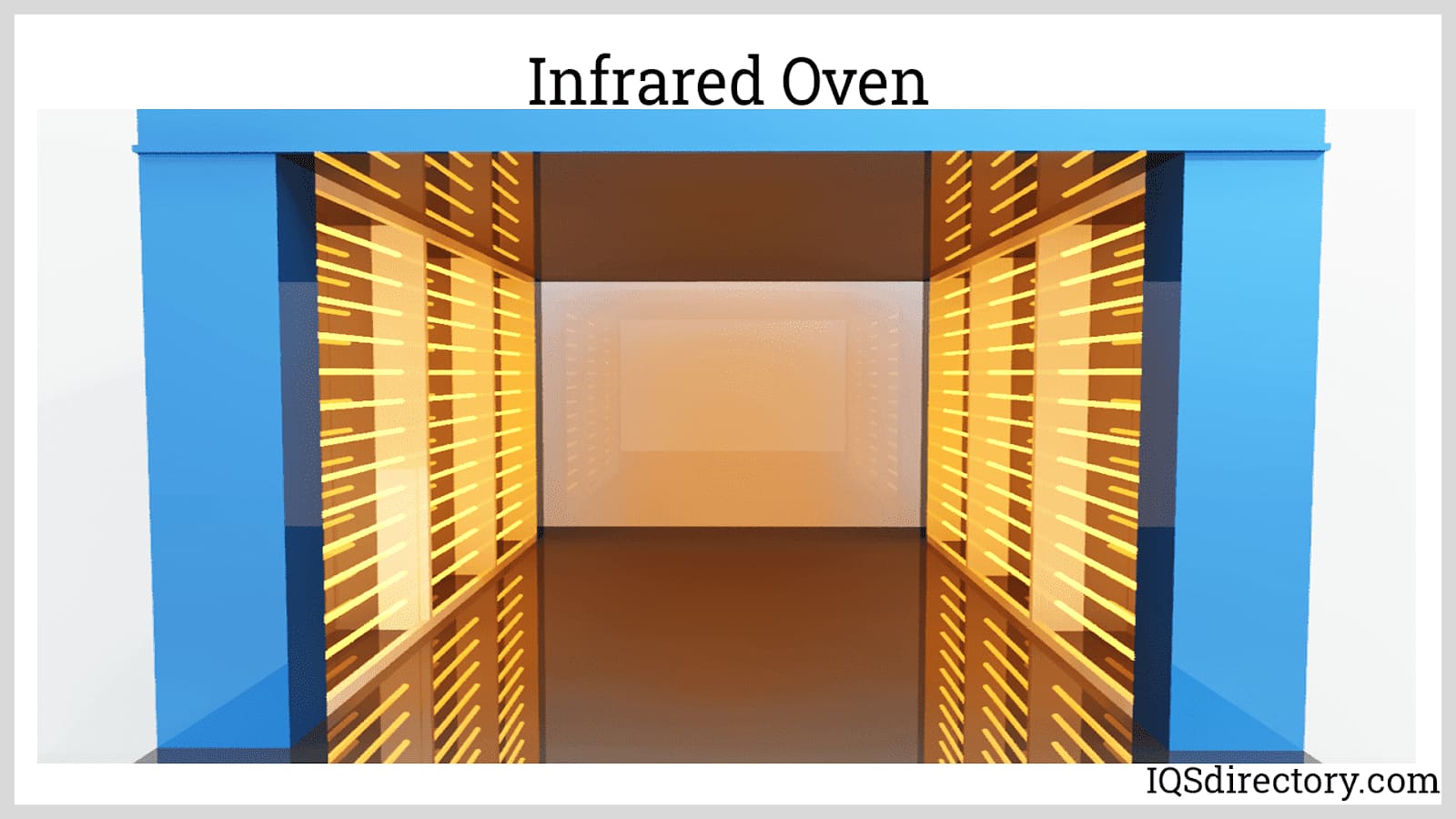

The thermoplastic particles begin to melt and gel, and as they cure they form the product's new protective coating. Powder coating ovens can come in several different forms. For industries that powder coat the same kind of product over and over, a conveyor oven system, which slowly moves products through a heated conveyor channel, allows for a steady stream of products to be treated continuously.

Batch ovens also make it possible to process several products efficiently. Depending on the size and configuration of a given batch oven, it may be able to treat products of different sizes simultaneously. Such a feature would be to the advantage of a company that produced custom powder coated products.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches