Heat treating ovens are used to alter the chemical and physical properties of metal or glass, including their hardness, tensile strength and toughness, through a three-step process of heating, cooling and reheating. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

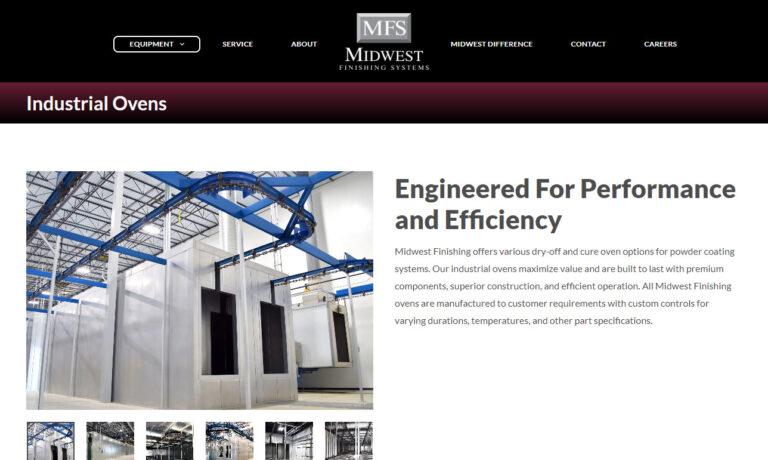

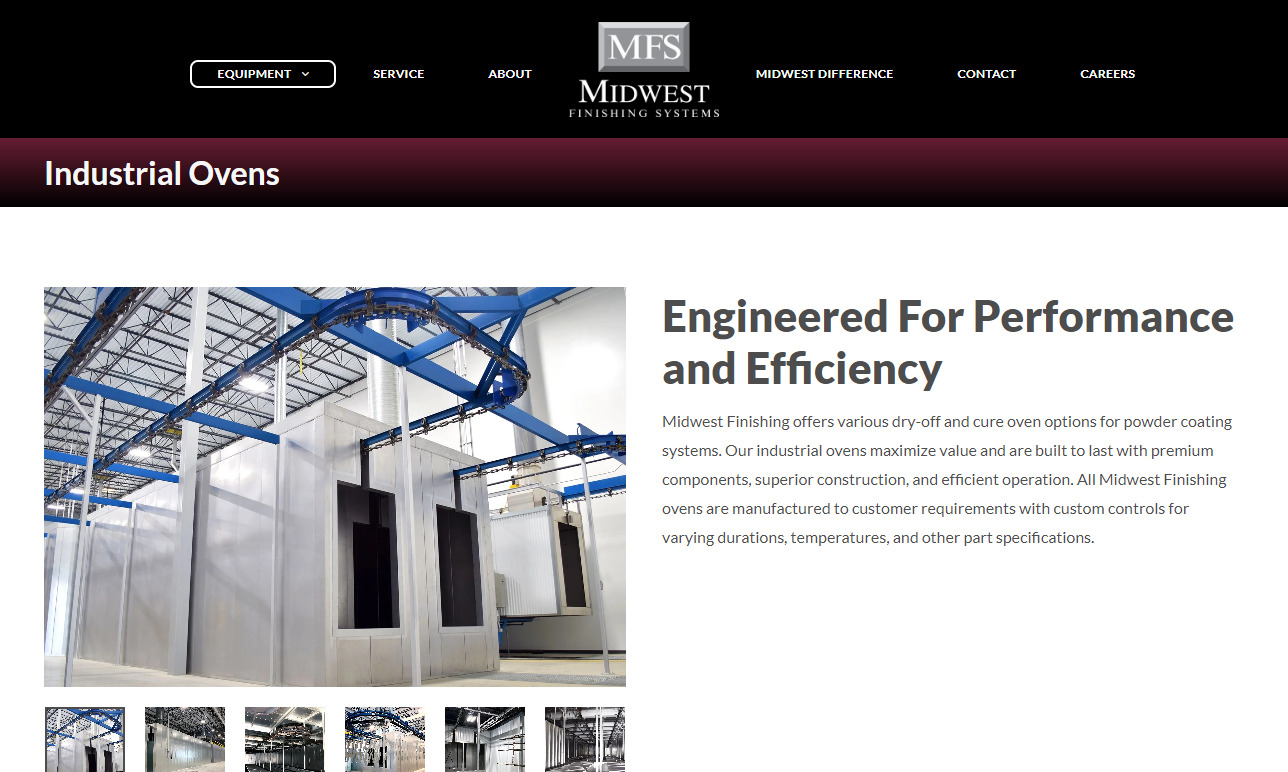

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Heat Treating Oven Manufacturers

Heat treating ovens may perform a number of heat processes, including quenching, case hardening, precipitation hardening, tempering and annealing. Quenching is the process of cooling a metal at a rapid rate. In ferrous alloys, this process will produce a harder metal, while in non-ferrous alloys, like copper, aluminum or nickel, it will produce softer metal.

Case hardening is a thermochemical diffusion process in which an alloying element, like nitrogen or carbon, diffuses into the surface of a monolithic metal. The result is a solid solution that is harder than the original material, which improves its wear resistance without compromising its toughness.

Precipitation hardening, also known as age hardening, is a heat treating process that increases the yield strength of most malleable materials. These materials include most structural alloys of aluminum, nickel, titanium, magnesium and some steels and stainless steels.

In superalloys, precipitation hardening is known to produce yield strength anomaly, which provides excellent high temperature strength. Tempering increases the toughness of iron-based alloys. Usually performed after hardening to reduce some of the excess hardness, tempering is completed by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

Finally, annealing is a rather general term that refers to the heating of a metal to a specific temperature and then letting it cool very slowly, at a rate that will produce a fine microstructure. The microstructure will be either partially or fully separated from the constituents.

Heat treating ovens are employed with this technique most often to soften a metal for cold working, to improve machinability or to enhance properties like electrical conductivity.

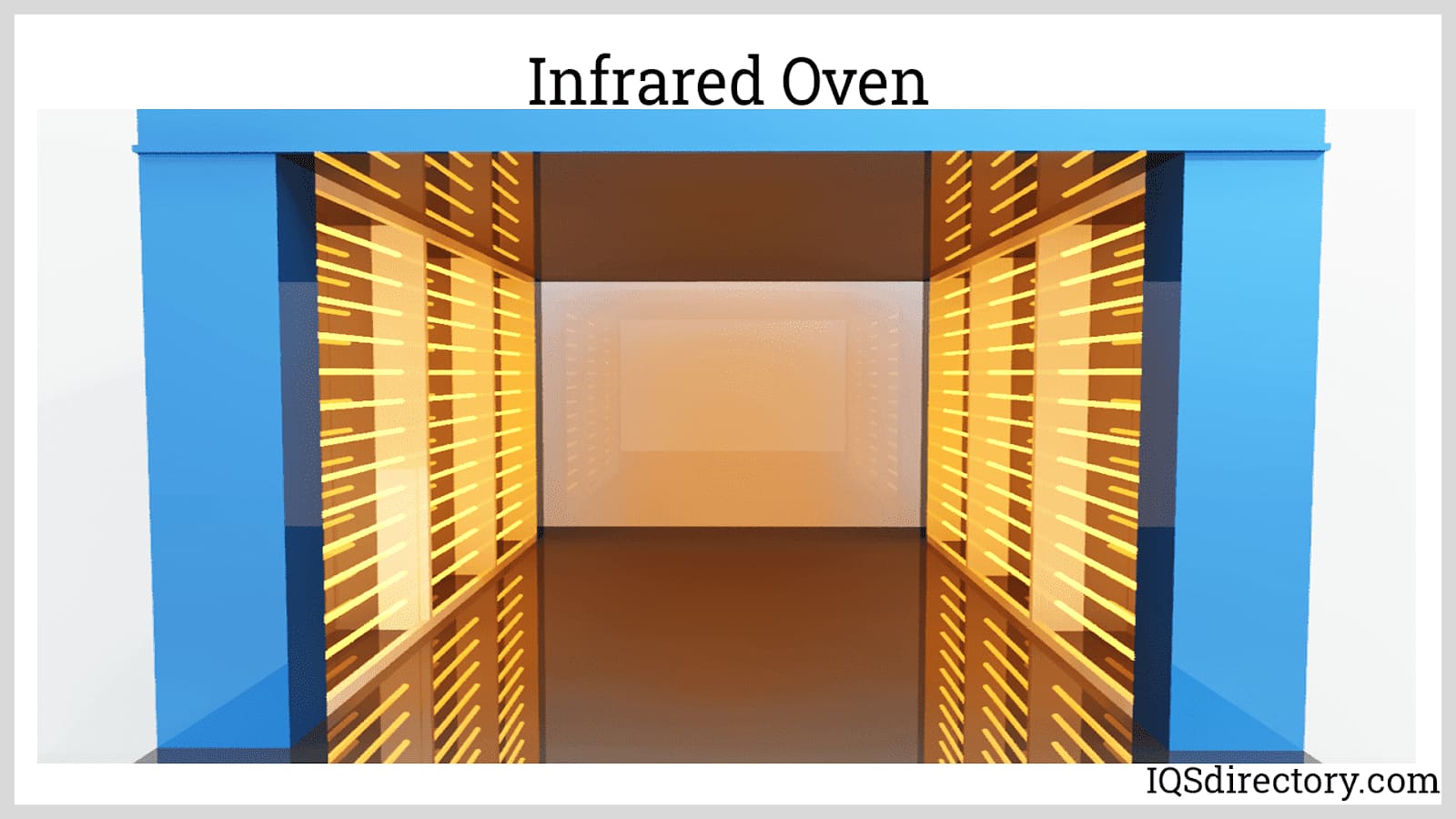

Heat treating ovens can generally be split into two groups: batch ovens and continuous ovens. Batch ovens are usually loaded and unloaded manually. Continuous ovens, on the other hand, have an automatic conveying system that provides a constant load into the oven chamber.

Industries in which heat treating ovens are employed include: aerospace, automotive, composite and specialty materials, medical, dental and military and defense. Heat treating serves these industries well by providing them with glass and metal that has improved strength, hardness and toughness.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches