A drying oven refers to equipment used to remove moisture from the chamber of an oven to dry samples as quickly as possible. This process works by introducing fresh dry air to the chamber and expelling the warm moist air simultaneously, allowing for rapid drying of the samples. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Drying Oven Manufacturers

What is a Drying Oven?

Drying ovens result in high-performance drying and heating. They can be used for evaporation, sterilization, baking, incubation, and other applications. Drying ovens also vary in size, capacity, and shape based on their reasons for use.

How Drying Ovens Function

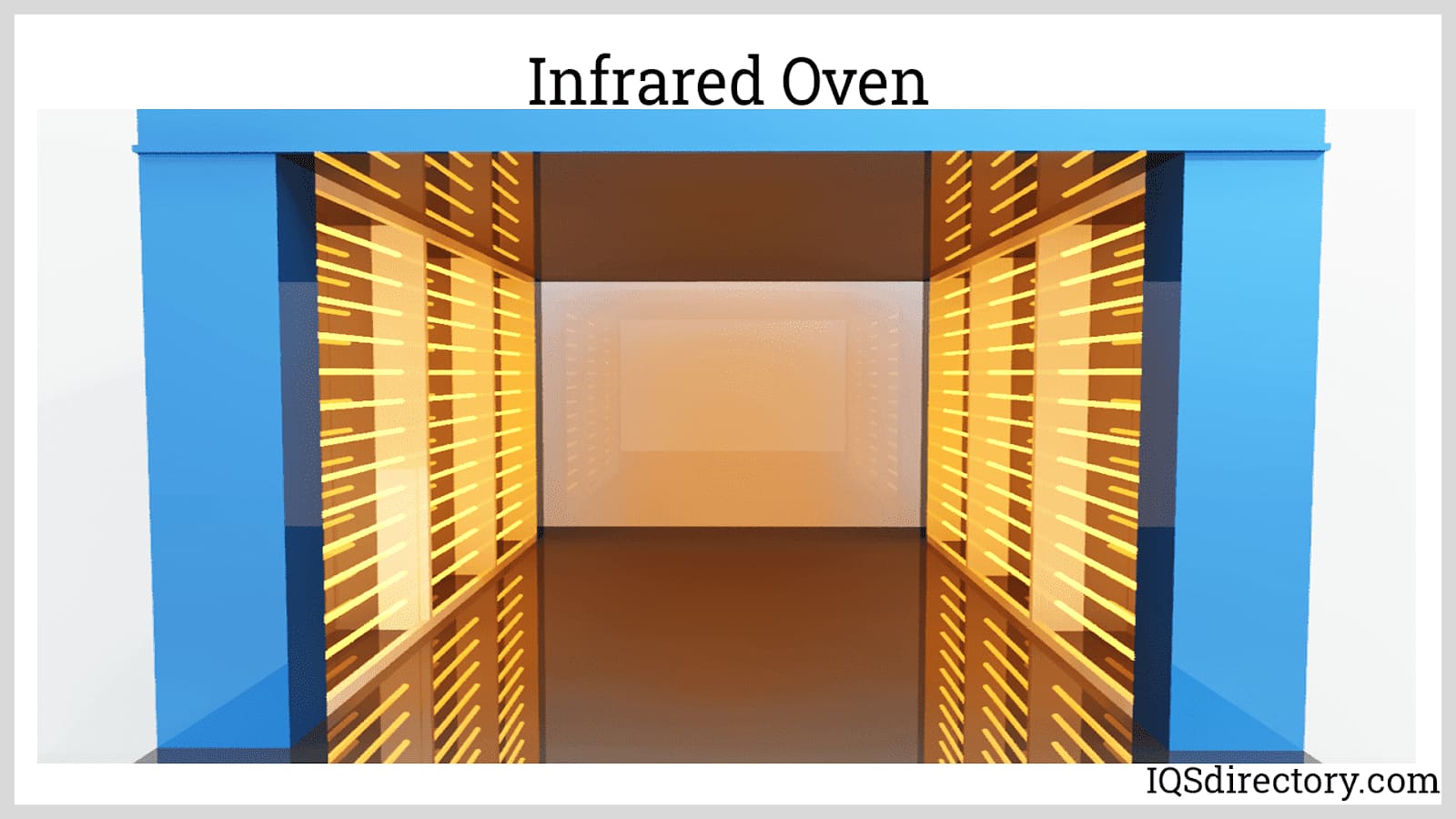

Drying ovens function by removing moisture, and this process begins as the chamber load experiences defined temperatures at atmospheric pressure inside the chamber.

Next, thermal energy enters the chamber by forced convection, radiation, or natural means. This is followed by the complete surface heating system assisting from the rear of the interior walls.

The dying occurs much faster with higher temperatures and drier air. This simultaneous heating and drying laboratory-given function causes the contained samples to dry, thus removing the contained moisture.

Types of Drying Ovens

Industrial ovens all share the same core concept but come in different types for different uses. Depending on the industry, industrial ovens vary in time and volume capacities, heating mechanisms, and other key elements.

Conveyor Dryers

Conveyor dryers are used in processes requiring the continuous production of small and medium-sized products. Conveyor dryers are also ideal in areas with automated mass production because they fit perfectly in most production lines.

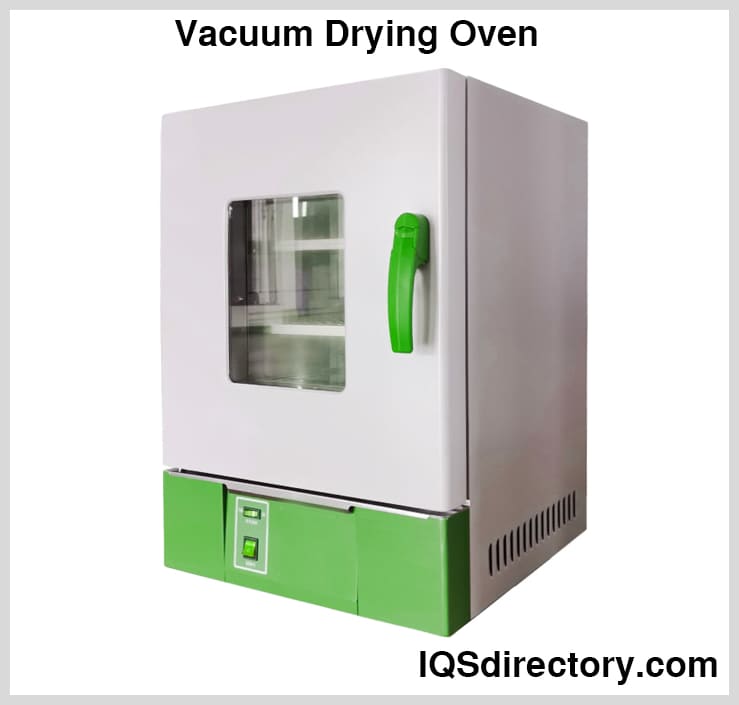

Vacuum Drying Ovens

Vacuum drying ovens are versatile machines used in most cases in engineering, research, and other industries. These industries may require drying in a low-pressure environment.

Vacuum drying ovens also minimize oxidation and may include a digital interface automated for monitoring processes.

Convection Drying Ovens

Convection drying ovens work to gently accelerate the dehydration process by relying on high temperatures. Convection drying ovens are ideal for processes including baking, pre-heating, sterilization, aging, and thermal storage.

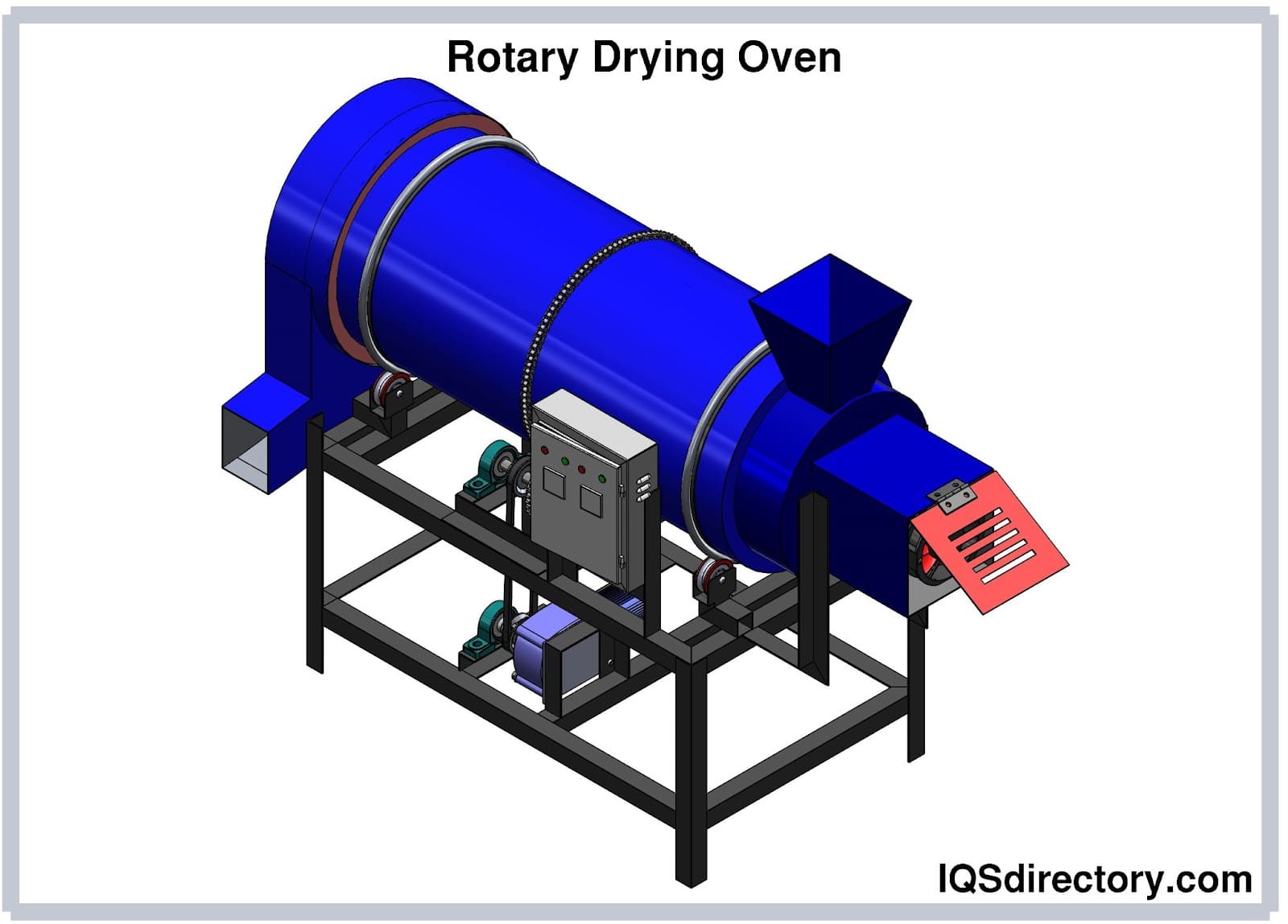

Rotary Drying Ovens

Rotary drying ovens are commonly used in the metal manufacturing industry. These types of drying ovens enable faster drying times without oxidation. Rotary drying ovens have an energy-efficient design that may also interlace with additional processes, allowing for low operating costs.

Flotation and Roll Support Web Dryers

Flotation and roll support web dryers are specialized drying ovens used in web and fabric coating, packaging, and textile manufacturing. These types of drying ovens usually feature a stable airflow and precise temperature control, improving overall efficiency.

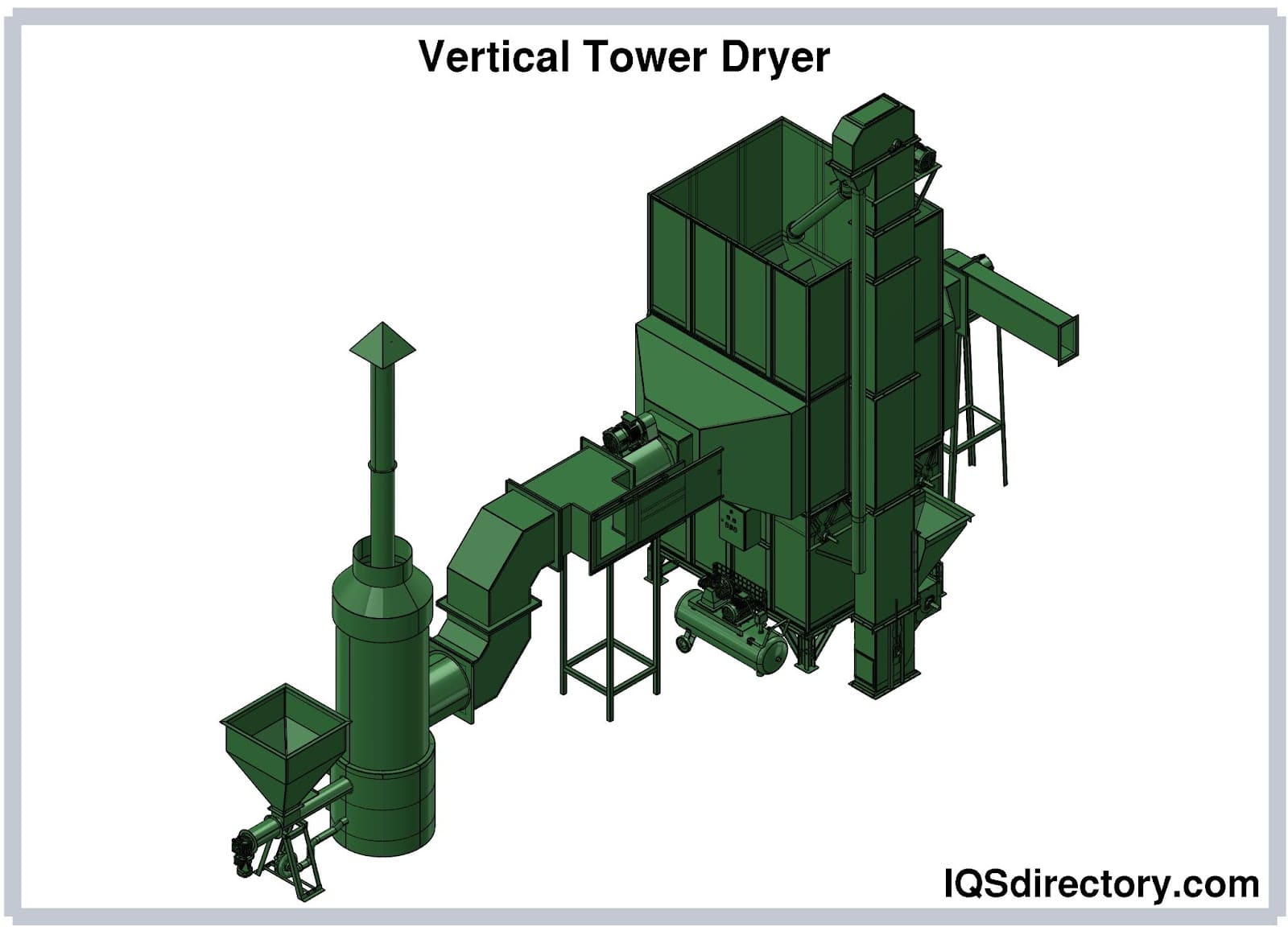

Vertical Tower Dryers

Vertical tower dryers are ideal in the sense that they make optimal use of space while at the same time adding an industrial drying oven for operation. These dryers can also help reduce overall costs while simultaneously improving quality and turnaround time.

Applications and Uses of Drying Ovens

Drying ovens can heat surgical cloths, blankets, infusion solutions, and rinsing solutions in hospitals and clinics.

In the electronics sector, drying ovens are used for drying components, burn-in testing, and degassing epoxy resins.

In the food sector, drying ovens are used for stability testing. Some other uses of drying ovens also include the aging or tempering of metals and plastics.

Selecting the Proper Drying Oven Company

To ensure you have the most constructive outcome when purchasing a drying oven from a drying oven company, it is important to compare several businesses using our directory of drying oven companies. Each drying oven business has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each drying oven business website using our patented website previewer to quickly learn what each drying oven company specializes in. Then, use our simple RFQ form to contact multiple drying oven companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches