Non-food industrial ovens, which include rotary ovens, are typically used to cure certain materials that are hardened through heat applications. To that end, rotary ovens are used to raise materials to a high temperature in a continuous, indexed or manual process, in order to accomplish heating applications. Typical heat processing applications performed by rotary ovens include: annealing, lean or cell based manufacturing, pre-heating, shrink fitting and stress relieving. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

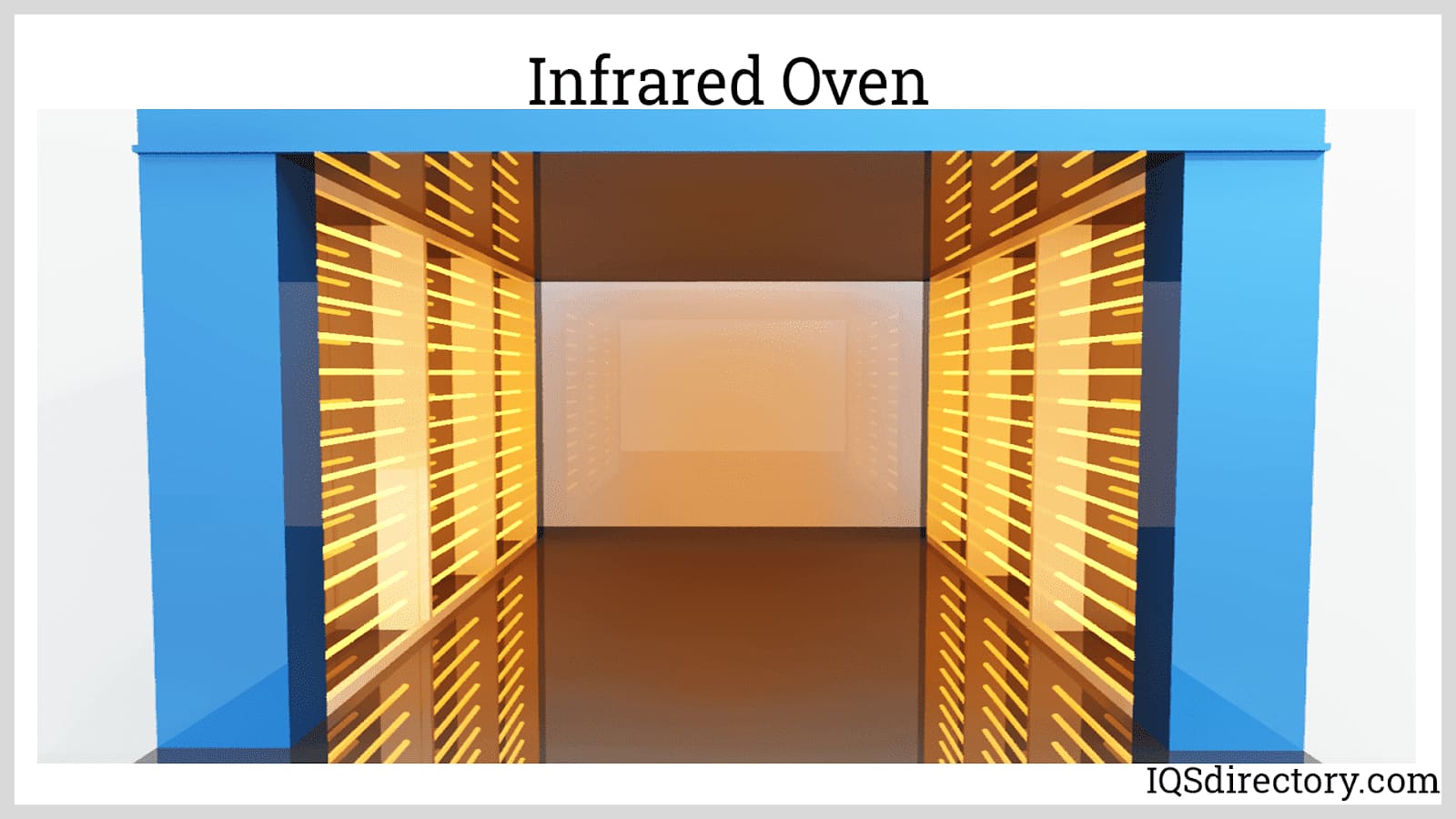

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

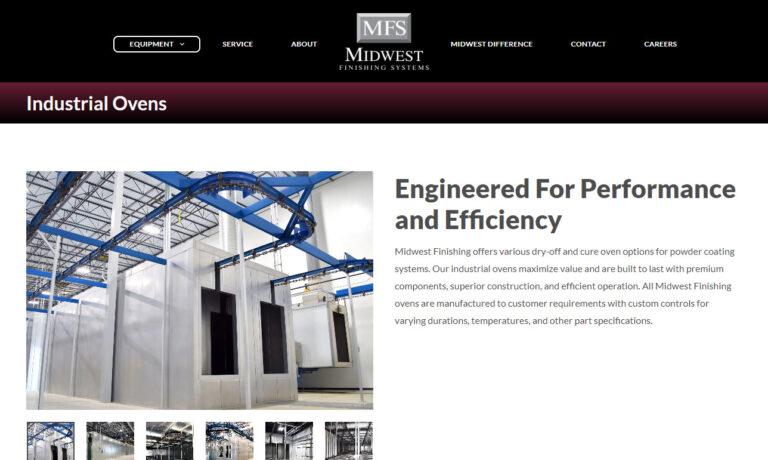

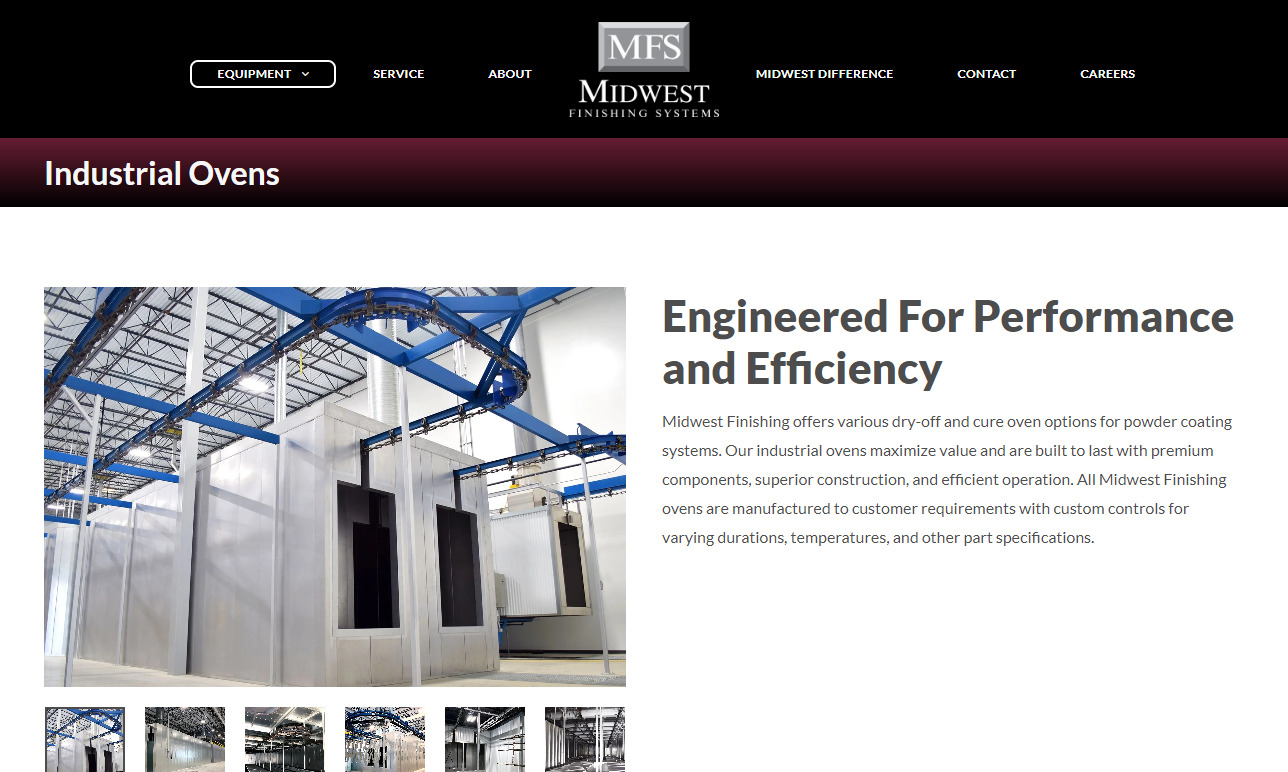

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Rotary Oven Manufacturers

Materials produced in rotary ovens include: cement, lime, refractories, metakaolin, titanium dioxide, alumina, vermiculite and iron ore pellets. Rotary ovens are also used to roast a wide variety of sulfide ores prior to metal extraction. Rotary ovens rotate the material within the heat chamber, where it may encounter a single or multiple heat zones.

A rotary oven may include optional features like: recirculation fans with high efficiency motors, inert atmospheres, can construction bodies, thermal and regenerative oxidizers, remote capabilities using industrial computer technology, UL or CE certified panels, PE certifications and programmable controls with HMI technology.

Rotary ovens may glean heat from a number of sources, including electricity, LPG, natural gas, fuel oil, steam and other fuel mixtures. Rotary ovens benefit many industries and applications, including aerospace, agriculture, automotive, heavy duty equipment, HVAC, motor, mining and transportation.

Rotary oven manufacturers will accommodate your specifications and standard requirements. Most manufacturers can build or modify your rotary ovens so that they conform to standards like: NFPA, IRI, FM, OSHA, JIC, NEC, UL and CE. Manufacturers may further check for quality through certain assessments, such as assessments for production goals, parts configuration and construction, part mass, temperature profile and in-facility test runs.

They may also test your rotary ovens for performance, accuracy, safety systems, air management and temperature uniformity. Discuss your application, specifications and requirements with potential manufacturers to find the right fit for you. A well-built and well-maintained rotary oven is a treasure.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches