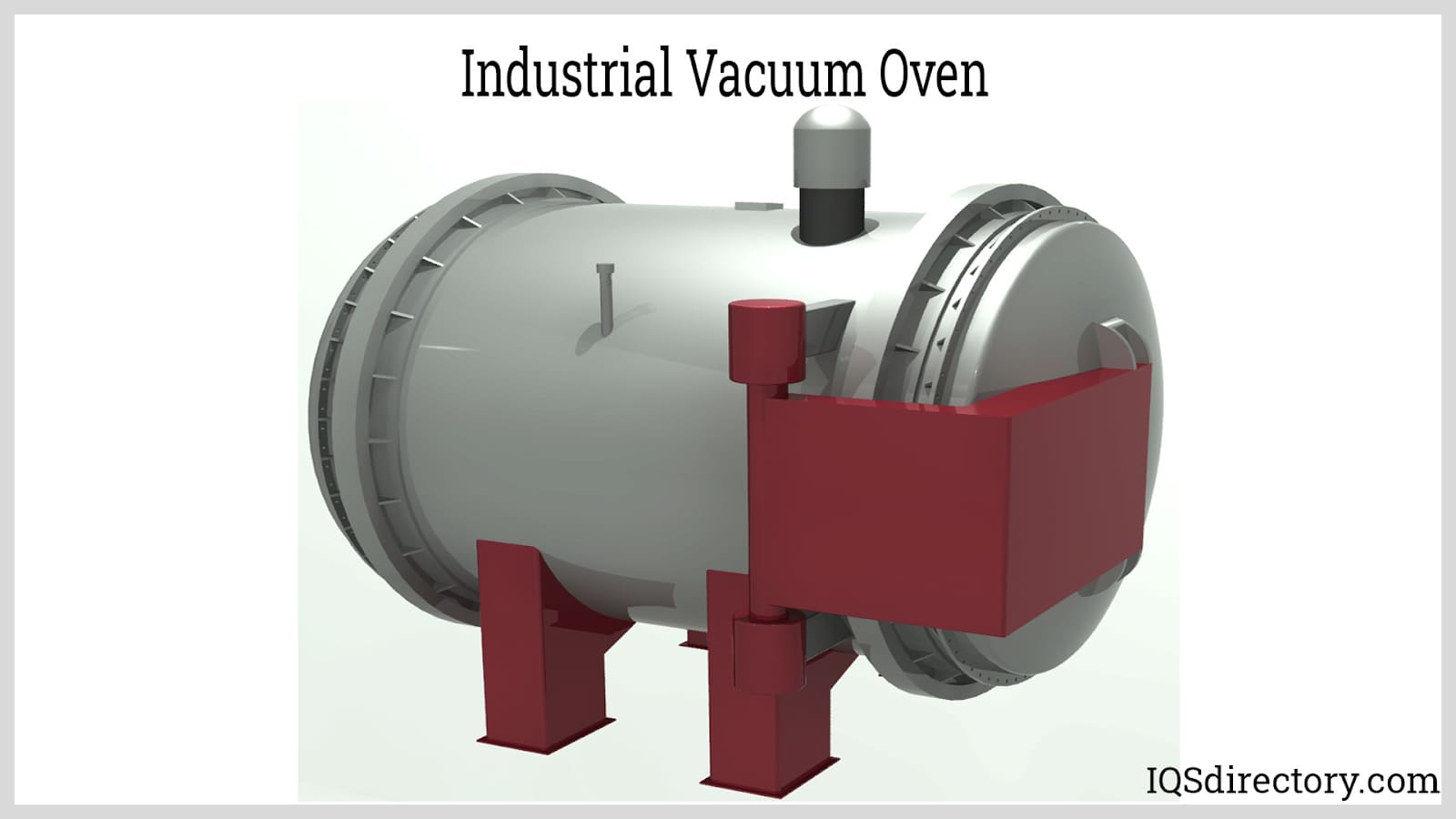

A vacuum oven is a versatile piece of laboratory equipment commonly used for delicate heating and drying processes. They are commonly used when drying very small parts or when dealing with removing flammable solvents like methylated spirits or alcohol. The oven usually functions at a steady temperature of around 3600 °F to 4500 °F (2000 °C to 2500 °C). Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

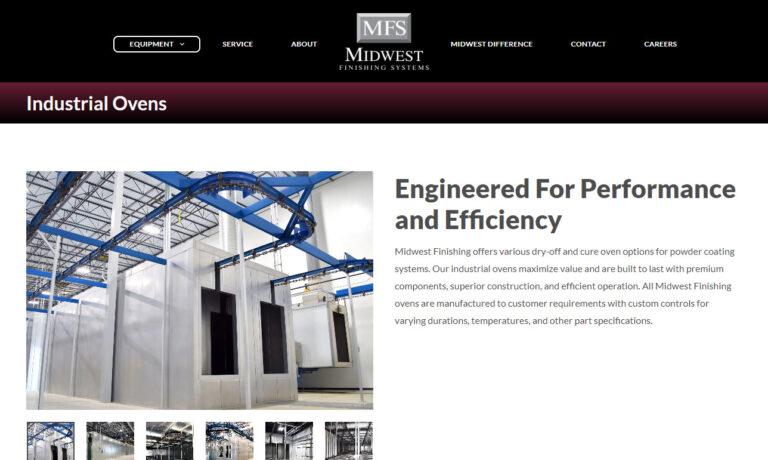

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Vacuum Oven Manufacturers

What Is a Vacuum Oven?

A vacuum oven is a versatile piece of laboratory equipment commonly used for delicate heating and drying processes. They are commonly used when drying very small parts or when dealing with removing flammable solvents like methylated spirits or alcohol. The oven usually functions at a steady temperature of around 3600 °F to 4500 °F (2000 °C to 2500 °C).

How Vacuum Ovens Function

Vacuum ovens are commonly used to remove moisture, gasses, or other possible unstable chemicals from equipment or other items while preventing any reactions. They are usually used at the final step in producing medical devices, epoxies, semiconductors, oils, and other packaged food products.

Drying items in a vacuum significantly reduces oxidation and ensures the gentle drying of delicate products. They also reduce the chances of exposing employees to harmful chemicals.

The vacuum oven is aptly named because it heats items much like an oven and is useful when a vacuum-sealed chamber is required. The vacuum chamber is the primary mechanism for drying items.

With reduced pressure in the vacuum chamber, the boiling points of most substances are reduced, ensuring that they completely evaporate unwanted substances without burning or damaging equipment. This is a similar phenomenon to how the boiling point of water is greatly reduced at high altitudes.

Specifications of Vacuum Ovens

The crucial parameters to consider when specifying vacuum ovens are oven temperature range, oven capacity, and pressure range. Temperature range refers to the maximum temperature at which the unit operates and can maintain the rated specifications.

Capacity refers to the total capacity of the interior space of the unit. Vacuum ranges for the vacuum ovens can be roughly or as low as (< 760, > 1 torr), a medium of (< 1, >10-3 torr), a high vacuum of (< 10-3, >10-8 torr), and sometimes an ultra-high vacuum of (< 10-8 torr) and other elevated pressures of (> 760 torr).

Types of Vacuum Ovens

There are two main types of vacuum ovens: electronic-controlled ovens and microprocessor-controlled ovens.

Electronic Controlled Ovens

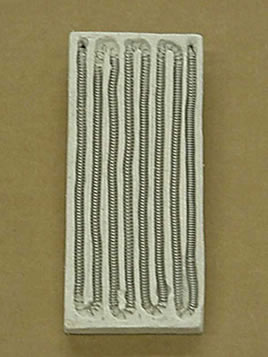

These types of ovens offer enclosed heating of elements to ensure stabilized and uniform heating. Overheating is reduced by the use of an electronic control backup. A panel in the front controls the primary temperature, purge gas, control valves, and vacuum gauges.

The gas and the vacuum system connectors at the back allow the user to replace the air with non-reactive gas. In addition, the user can look through the window to see the temperature within the chamber.

Microprocessor Controlled ovens

Microprocessor-controlled ovens provide an array of self-testing indicators, a thermostat, and controls to prevent damage to samples. It can be programmed to set on or off cycles, and the front panel alerts users to open thermocouples, changes in temperature, or any other occurrences.

Applications of Vacuum Ovens

Vacuum ovens are useful in removing excess moisture within a substance through the effects of high temperature and reduced pressure. This functionality is very common in cleaning medical equipment and separating moisture from oils.

The vacuum pump reduces the overall pressure in the chamber while the oven provides the required heat energy. Other common uses are curing or drying textiles, rubber, and ceramics. The use of vacuum ovens also simplifies botanical extractions.

Advantages of Vacuum Ovens

Vacuum ovens are favorable because they can reduce the substance's boiling point and hence are suitable for heat-sensitive substances. They are also suitable for samples that do not dry easily, such as very small granular samples.

The vacuum-drying method is suitable for cleaning complex mechanical parts. The inert condition deals with the explosion of oxides. Vacuum ovens also ensure that equipment handlers are not affected by the dangerous chemicals that need to be cleaned from equipment.

Choosing the Correct Vacuum Ovens Manufacturer

To make sure you have the most beneficial outcome when purchasing Vacuum Ovens from a Vacuum Ovens Manufacturer, it is important to compare at least 4 Suppliers using our list of Vacuum Ovens companies. Each Vacuum Ovens Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Vacuum Ovens business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Vacuum Ovens companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches